biodegradable plastic manufacturer

Our mission is to produce biodegradable plastic that can challenge the dominance of oil-based polymers, and ultimately replace them completely.

PLA plastic are made from cornstarch – a natural material with high regeneration and biodegradability, totally safe for users’ health and eco-friendly.

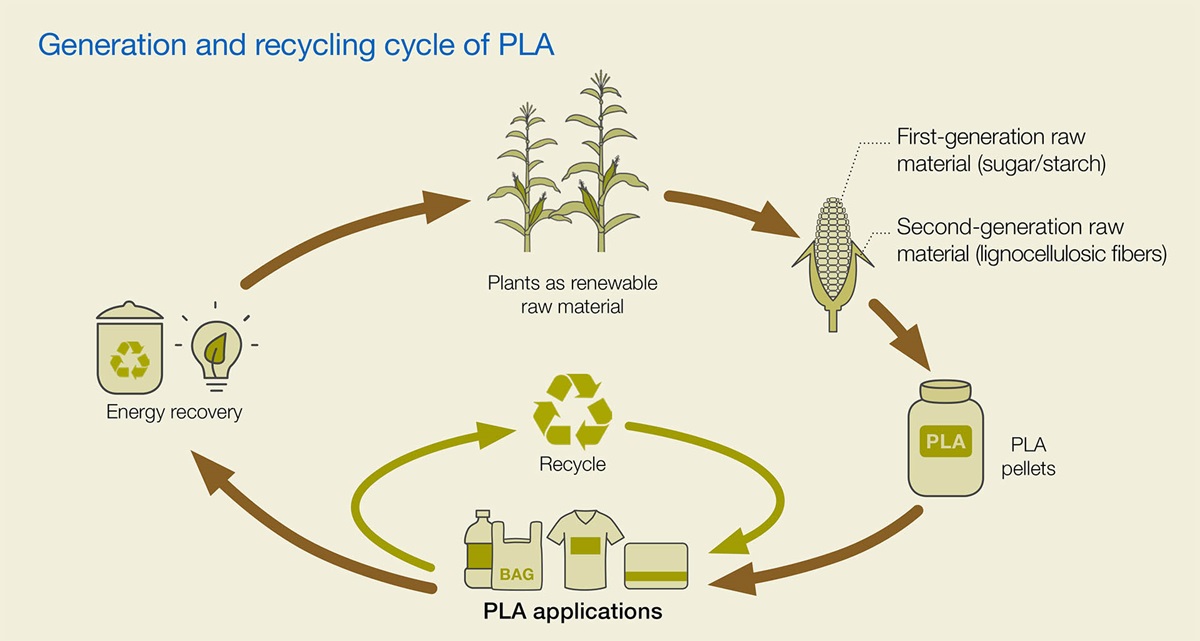

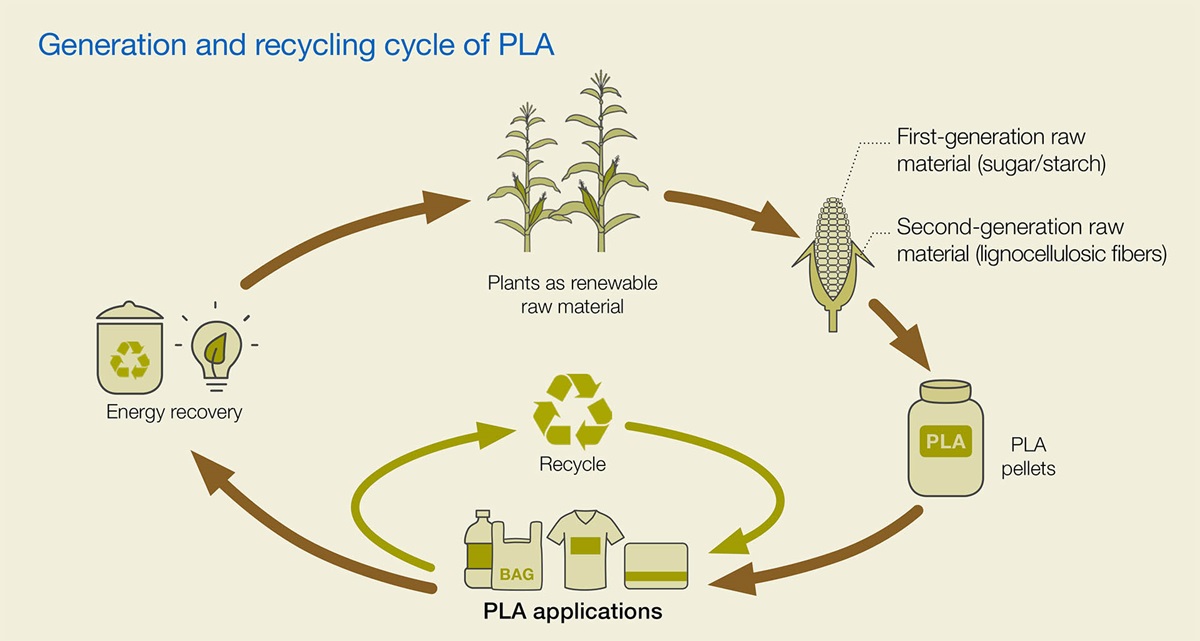

This plastic is a renewable material. After use, they can be decomposed by microorganisms, through a process of industrial biodegradation, into biomass that can be used as fertilizer for plants.

The surface of PLA plastic has magnificent permeability properties, creating favorable conditions for microorganisms to promote the natural decomposition process. Under the right conditions, PLA plastic can decompose into CO2, water and biological humus by the action of microorganisms. These substances do not pollute the environment and are good for arable land

Leading technology for biobased PLA plastic

Dawn have been researching bio-based, bio-compostable, recyclable plastic materials for many years. Dawn have produced a new generation of plastics using bio-renewable materials and, in the future, lignocellulosic sugars. Lignocellulosic sugars are second-generation raw materials extracted from biomass such as straw, corn stover, bagasse or wood chips.

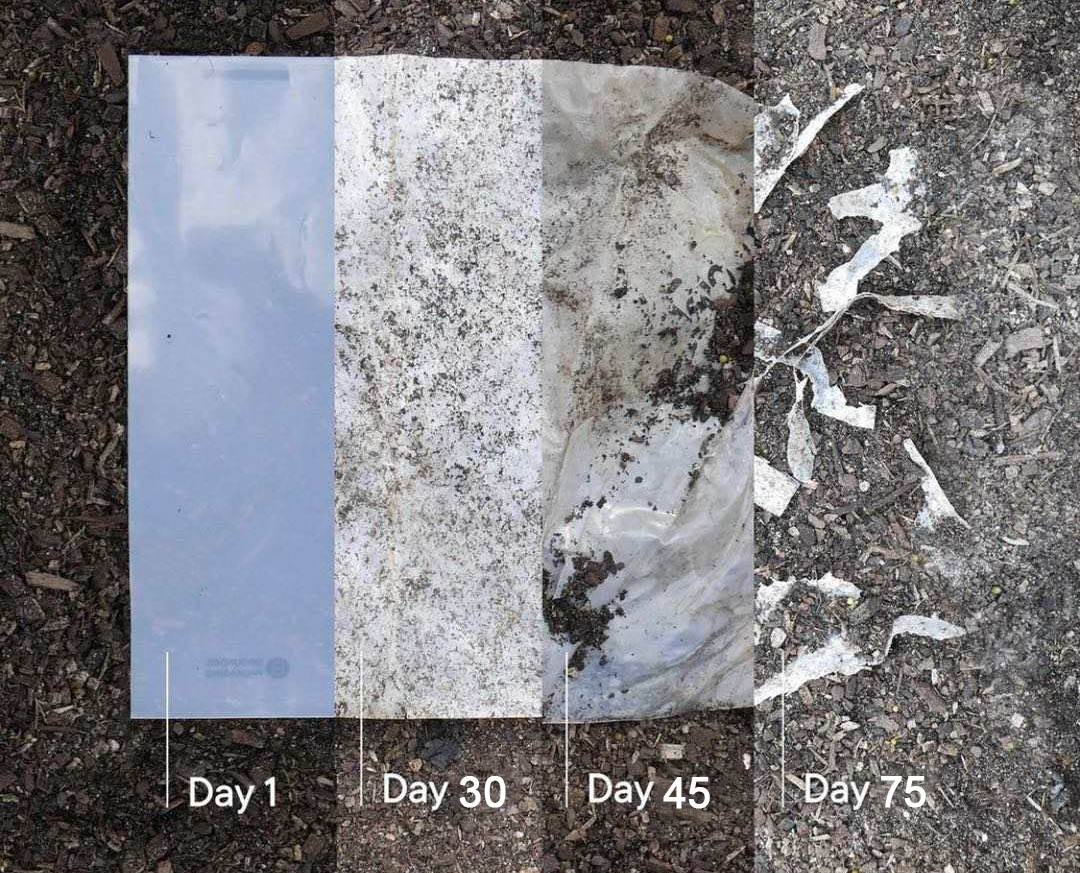

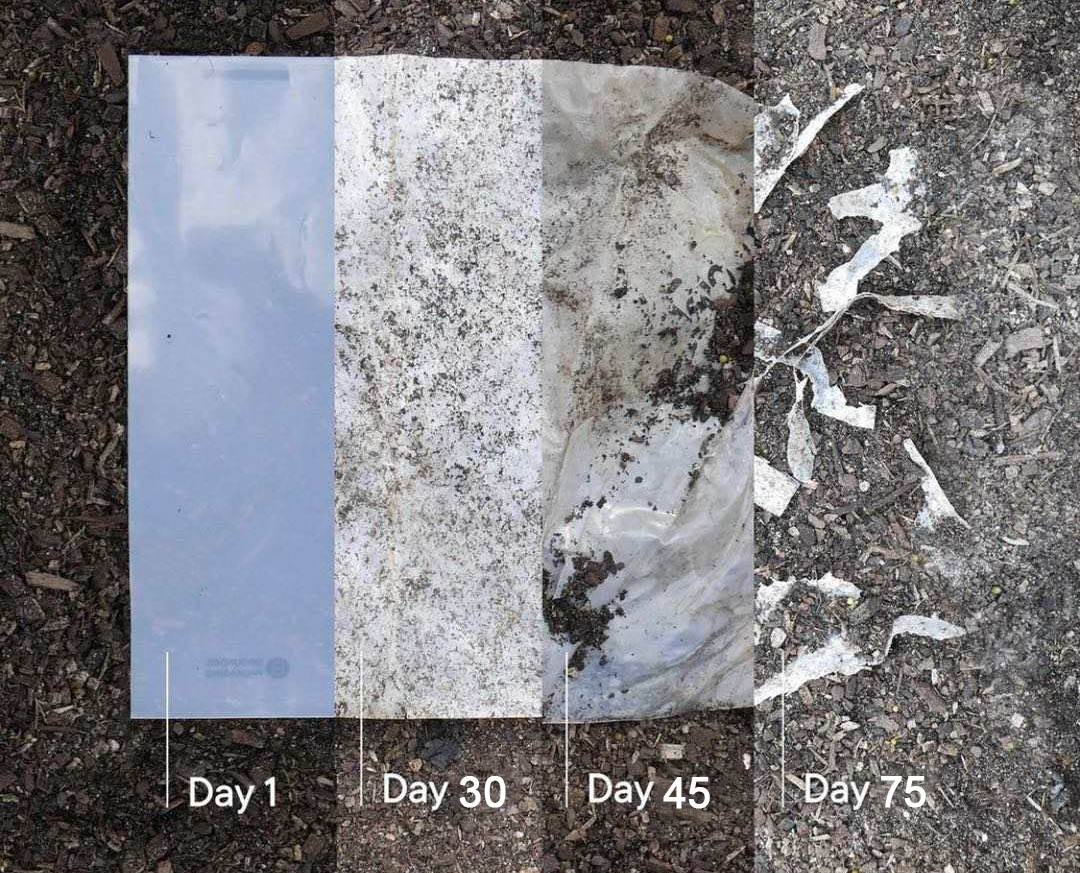

degradation process

The natural decomposition time of PLA plastic is very short, only taking a few months. When other traditional plastics need more than 100 years. Thus, this plastic offers many positive effects on protecting the environment.

Biodegradable RFQ

The degradation of biodegradable materials needs to occur under suitable conditions such as temperature, humidity and microorganisms, and will not be biodegraded during daily use or storage period.

The degradation conditions and environments of biodegradable materials can be various: in compost, soil, river water, seawater and other environments, degradation can occur when the temperature and humidity and their microorganisms are suitable. But because composting is a controlled condition, the process of biodegradation is relatively easier to control.

In natural soil, conditions such as temperature, moisture, and microorganisms are uncontrollable compared to composting. At present, from the application of biodegradable plastic film and the results of laboratory and field degradation experiments, most biodegradable materials can be biodegraded under field soil conditions: PBAT, PHA, PCL, PBS, etc. under normal climate conditions, 5 Under the condition of monthly burial, it can be completely degraded without affecting plants. complete degradation within.

At present, the global production capacity of biodegradable materials is about 1 million tons, with an annual growth rate of about 20% to 30%. At present, biodegradable materials such as fossil-based PBAT are still the main sources. Among these materials, the biodegradable materials prepared from corn starch are mainly polylactic acid. At present, the global production capacity of polylactic acid is about 280,000 tons/year, and the apparent consumption is about 160,000 tons/year. Even if the construction of polylactic acid production capacity according to some reports has been realized in recent years, the biodegradable materials prepared by using corn starch as raw materials are only one million tons, which will not have a fundamental impact on food.